Substantial change of machines

The Federal Ministry of Labor and Social Affairs ( BMAS ) in Germany deals with various legal regulations and regulations to ensure the safety and health protection of employees in various work environments. An important aspect in this area is the Machinery Directive, which sets out requirements for the safe operation and use of machines. Under the Machinery Directive, it is crucial to consider changes to machinery carefully, particularly when significant changes are involved.

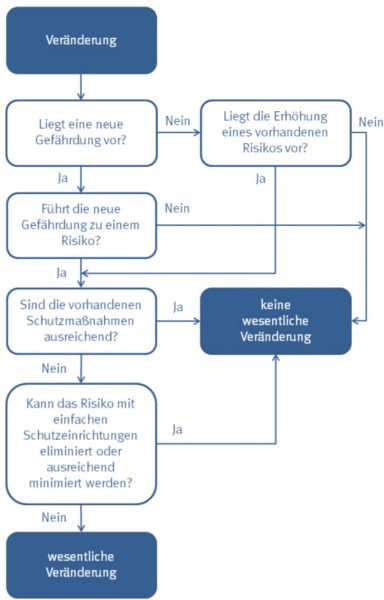

If changes exceed the established limits, the modification is considered material. The effect of this is that the entire machine is considered new and the person making the change becomes, in practice, the manufacturer. The assessment of whether the change made should be classified as significant is the responsibility of the person carrying out the modification.

Three cases must be taken into account

1. If no additional hazard or increase in risk occurs, the machine can be considered safe even after the modification. In this case, additional safety measures are not necessary and this is not a significant change.

2. Even if there is a new hazard or an increase in risk, the existing safety measures may be sufficient to continue to classify the machine as safe. Therefore, no additional safety measures are required and this is not a significant change.

3. If a new hazard or increase in risk is identified and the existing safety measures are not sufficient, there may be a material change and further assessment steps are required.

First, it must be determined whether it is possible to restore the machine to its original safe state by implementing simple protective devices without increasing the risk compared to the initial state. If this is possible, the change can generally be considered non-significant. Otherwise, a detailed risk assessment is required. First, the potential extent of damage that can be caused by the existing hazard is examined, taking into account both personal injury and property damage.