What is this article about?

The purchase of a new machine or a used machine is often a special investment in manufacturing commercial enterprises. But what happens if problems suddenly arise after delivery and commissioning of the new or used machine? The joy of the new acquisition can quickly turn into frustration, dissatisfaction with financial consequences. In such situations, it is crucial to keep a clear head and proceed systematically to determine whether there are indeed faults and the machine is defective.

In this article, I address some key aspects of this issue and how to deal with it when there is (apparently) a defective delivery of a machine. A defective machine equals a multitude of problems to be managed. This is not only to determine whether the machine is broken, but also whether it meets expectations and original specifications. Often there are technical discussions between the customer and the manufacturer or supplier, and in such moments it is important to proceed in a factual as well as structured manner in order to clarify the matter.

Preparation of the machine purchase

The first question to be answered is: buy the machine new or used?

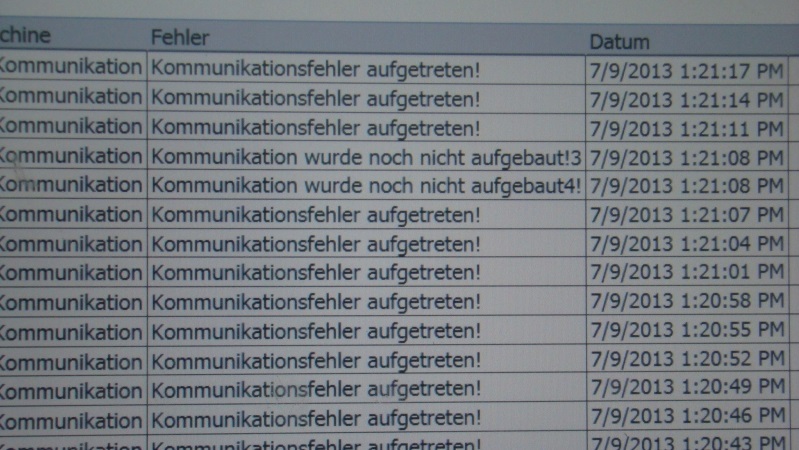

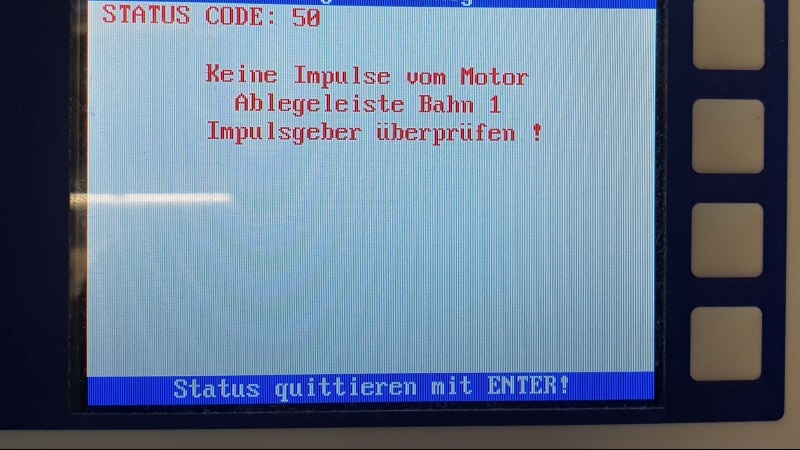

Defective machine after defective delivery with permanent error message. Operator diagnosis: “Machine broken”.

Buy new or used?

The purchase of machinery is a decision of great technical as well as economic importance, not only financially, but also in terms of operational efficiency and long-term investment in the productivity of a company. When buying a new machine or purchasing a used machine, there are numerous factors that should be taken into consideration.

Both options have their advantages and disadvantages.

Exemplarische Vorteile neuer und gebrauchter Maschinen.

Neue Maschinen … Gebrauchte Maschinen …

stehen für höhere Zuverlässigkeit durch neuesten Stand. Dies führt zu einer höheren Betriebszuverlässigkeit und geringeren Stillstandszeiten. sind in der Regel deutlich günstiger als neue Maschinen

beinhalten neuesten Technologien und Innovationen, was die Effizienz und Produktivität steigern kann. sind oft sofort verfügbar und können kurzfristige Bedürfnisse erfüllen.

können an spezielle Bedürfnisse angepasst, was eine maßgeschneiderte Lösung ermöglicht. haben oft eine nachgewiesene Leistungsgeschichte.

entsprechen (hoffentlich) aktueller Maschinensicherheit. verfügen fast immer über CE-Kennzeichnung, aber gilt das noch?

The decision between buying a new or used machine depends on several factors, including the available budget, the intended use, the planned useful life and the availability of used machines on the market.

Exemplarische Nachteile neuer und gebrauchter Maschinen.

Neue Maschinen … Gebrauchte Maschinen …

bedeuten höhere Anschaffungskosten. stehen oft für größere Reparaturkosten.

erfordern deutlich längere Lieferzeiten. bereiten ggf. Probleme mit Verfügbarkeit von Ersatzteilen.

haben meist längere durchschnittliche Lebensdauer haben eine deutlich geringere Restlebensdauer.

erhalten teilweise eingeschränkte Garantien.

erfüllen oft nicht die Anforderungen an Sicherheit nach BetrSichV2015.

Define requirements for machine to be purchased before machine purchase

Before embarking on the purchase of a used or new machine, it is crucial to clearly define your own requirements and needs so that the machine you purchase will meet your operational requirements. This is not only about the technical specifications of the machine, but also about legal requirements related to the operation of machinery and the safety of workers.

The often later party diagnosis “machine broken” can also result from poorly or not defined requirements.

- Clear definition of requirements:

Before a machine is sought and ordered, purchasers/operators should prepare a detailed specification or requirements list as a guide. These documents serve as a guide and contain all the essential requirements and specifications that the machine must meet. These include:

- Technical requirements, such as machine performance, size, capacity, speed, accuracy and other technical details that are critical for the intended use.

- Operating conditions at the intended place of operation.

- Safety requirements must be met, which means the requirements of BetrSichV2015, especially for used machines, often a knockout criterion.

- Regulatory requirements, such as other legal regulations and standards that apply to the operation of the machine at the place of operation, including certifications and conformity requirements.

Nightmare for purchaser / operator of machines: The new machine “stands permanently” and there is a defective delivery. What to do?

- Consideration of legal requirements:

It is essential that current legal requirements for the safety of employees working with the machine are met, such as:

- Safety guidelines: This may include aspects such as machinery directive and occupational health and safety laws.

- Environmental regulations: Are necessary standards met?

- CE marking (in the EU): Is it present and does the built machine still comply with the (former) declaration of conformity?

- Involve experts:

Experienced surveyors and experts can be an invaluable help in defining your requirements. They have extensive experience in many similar cases and can offer valuable insight and recommendations. These professionals can help you ensure that your requirements are reasonable, realistic, and actionable.

Defective machine: steps to be taken when technical defects and faults occur

The occurrence of technical defects and faults in machines can be a challenge in any operation; after all, the defective machine should be ready for use again quickly.

The first and most important step is to accurately document the potential defect and communicate it to the manufacturer. This includes the time, place and circumstances under which the error occurred. The exact description of the error and its effects is crucial.

Suppliers or manufacturers have the right to rectification.

This is an important protection mechanism that ensures that the defective machine will be repaired or replaced if there is a defective delivery and the machine was handed over broken.

If there is a defective machine, however, the decisive questions to be clarified are:

Is there actually a defective delivery?

Does the machine correspond to the order including specification?

These essential questions can be clarified emotionlessly through the involvement of professional experts or surveyors. Professionals in the technical forensic machinery environment can examine the condition of the machine, determine the cause of the problem, and document the evidence. This is particularly important in order to substantiate the party claim of the ordering party or operator in the event of legal disputes or negotiations.

Legal basis for rectification

The right to rectification of a defective delivery is regulated in the German Civil Code (BGB) and provides protection for the purchaser and subsequent operator when purchasing a machine if the delivered goods are defective or faulty. This right is based on the provisions of §§ 437 ff. BGB. Here are the main points regarding the right to rectification:

- notice of defects (§ 377 BGB):

The buyer must report defects in the delivered goods immediately upon receipt of the goods. “Immediately” means that this should be done without culpable hesitation as soon as the defect is discovered. The complaint should be made in writing or in another suitable form.

- Claim for rectification of defects (§ 437 BGB):

The Buyer has the right to demand that the Seller remedy any material defects (rectification). This means that the seller is obliged to repair or replace the defective goods if this is technically possible and economically justifiable.

- Setting a deadline (§ 439 BGB):

As a rule, the buyer must set the seller a reasonable deadline for rectification, unless such a deadline is dispensable under the circumstances (e.g. in the case of obvious and serious defects).

- Refusal to rectify the defect (Section 439 (3) of the German Civil Code):

If the seller refuses to remedy the defect or if the remedy fails, the buyer has the right to withdraw from the contract, to reduce the purchase price or to claim damages.

- Limitation (§ 438 BGB):

The claim for rectification of defects shall expire within two years from delivery of the defective goods. However, in some cases, this period may be extended.

These general statements are no substitute for legal advice. When technical problems arise in connection with the purchase of a machine, legal problems are often the result. For this reason, it is advisable to always take an experienced lawyer on board as a party after a substantiated technical expert opinion on the problem.

Exemplary recurring error message of a machine purchased used. Stands the operation waiting consequential damages, such as failure damage, penalties, etc., when a machine is broken.

Usual views of purchaser and supplier

In the event of a potentially defective delivery of a machine, the different views and positions of purchasers and suppliers are often characterized by written e-mail communication. This can usually proceed in several phases until the “proverbial bang” and can include the following common positions:

Views of the supplier or manufacturer are often:

- Qualification of the personnel: The supplier or manufacturer often tends to doubt the qualification of the personnel at the purchaser. This is done in order to blame possible faults or defects of the delivered machine on the side of the purchaser.

- Denial of Defects: In most cases, the supplier initially denies the existence of defects or a defective machine. This is often done to avoid financial obligations for rework or repair.

- Demand for final payment: If the communication between the parties is tense and the possible technical problem has not been solved, the supplier often demands the final payment for the delivered machine for further action. This is sometimes seen as the final step in escalation to put pressure on the purchaser.

Views of the purchaser or operator are often:

- Defective delivery and defective machine: The purchaser is convinced that there is a defective delivery and a defective machine. This is based on his “observations” and possibly reports from co-workers.

- Refusal to make final payment: due to the alleged defects, the purchaser often refuses to make the final payment in order to put pressure on the supplier and ensure that the problem is corrected.

- Necessity of evidence: In order to support its own claims, the purchaser shall endeavor to collect evidence of the alleged defects. Although this tends to be the right step, 99% of operators/orderers do not take it fully and substantiately because they simply lack experience in dealing with such situations. Professional experts help here in a very targeted manner.

If there is damage or a proven defect, the following shall apply

the costs of the expert / surveyor are a damage item and can be claimed by the party responsible (manufacturer / supplier).

In many cases, written communication between the parties can become strained if the problem is not resolved quickly. This can lead to escalation, often resulting in legal action. At this stage, experienced experts are critical. You can clarify the issues in dispute in a factual and unemotional manner, gather evidence in a substantive and focused manner, and help find an amicable solution or prepare for potential litigation. This process can expedite clarification and make the legal process more streamlined.

Preservation of evidence by experienced technical experts for machinery and equipment

Faults and defects in machinery and industrial equipment are ubiquitous in the world of mechanical engineering and are among the challenges that manufacturers and operators face on a regular basis. In such situations, fundamental questions arise:

What was contractually agreed, and what was actually delivered?

Clarification of these issues forms the core of any dispute in connection with technical defects and deficiencies.

Unfortunately, the parties involved often tend to get lost in non-essential details during discussions. This can complicate and prolong the process of problem solving. When external lawyers are involved in such matters at an early stage, the focus quickly shifts from technical aspects to legal issues. This can lead to the original technical conflict being taken in a completely different direction, which can result in a lengthy and costly legal dispute. This is especially the case when the legal presentation has not been adequately prepared for the technical issues.

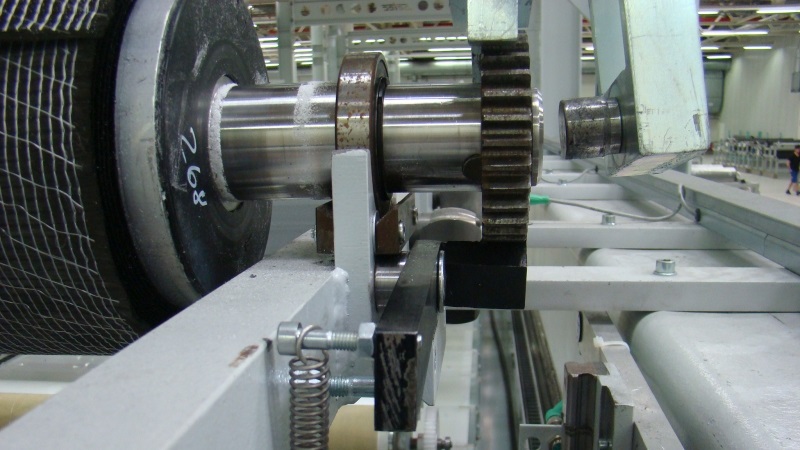

Massive abrasion of a machine purchased second-hand: Many technical issues need to be clarified.

In this context, expert opinions on the preservation of evidence in the field of “machinery, mechanical engineering and industrial plants” play a decisive role. These expert opinions serve to document deviations from the contractual agreements and to clarify technical issues. They are often prepared by knowledgeable experts and reviewers who have both in-depth expertise in mechanical engineering and an understanding of the technical and legal constraints.

As a rule, the commissioning of an expert opinion for the preservation of evidence on a machine or industrial plant takes place when the client is of the opinion that the delivered machine or plant does not meet the agreed requirements and thus his expectations have not been fulfilled. These expert opinions are indispensable for gathering objective and fact-based information that can serve as a basis for resolving disputes.

Overall, the preservation of evidence plays an important role in dealing with technical problems in the industry when a defective machine has been delivered and there is a defective delivery. It enables a

factual and professional clarification of contract performance issues and prevents technical disputes from being dragged to the legal level at an early stage without adequate substantiation at the technical level.

Long and expensive litigation or quick, alternative solution?

In reality, in my many years of experience, I have found that there are situations in which both the purchaser and the supplier or manufacturer strive to ultimately find a common solution. While this solution may require some sacrifice on both sides, the overall goal is to quickly resolve the technical issue.

In most cases, legal disputes related to technical issues, especially purchase prices of industrial machinery and equipment, have high amounts in dispute. These disputes are often settled in court after protracted litigation, if the technical presentation was prepared professionally and soundly. Therefore, it is crucial to be extremely well prepared and act professionally in such situations. In this way, it is also possible to influence a court expert who is commissioned in the course of a lawsuit in a target-oriented manner by means of a party expert opinion that has been prepared in a professionally competent and factual manner.

However, it is also possible to settle technical disputes between the parties, in most cases between the purchaser and the supplier/manufacturer, out of court by means of arbitration opinions or technical mediation procedures. I have seen several examples where parties in such proceedings found a solution in a timely manner that was ultimately more efficient and cost-effective than protracted litigation with an uncertain outcome.

In this context are

Arbitration and mediation are always a sensible option in technical disputes,

that reach amounts in dispute in the six-figure euro range or even in the millions. With such large sums it is advisable,

to have the preservation of evidence carried out by experienced professionals, as these costs may be claimed by the party causing the damage or its liability insurance in the event of an established damage.

Overall, it is evident that careful preparation and a willingness to find out-of-court solutions to technical conflicts offer an efficient way to protect the interests of both parties while addressing technical issues in a timely manner. This can significantly help avoid expensive and protracted litigation.

If the newly delivered machine does not work, frequently stops and breaks down, the conflict is pre-programmed by the defective machine.

Tips to avoid future problems when buying machines

Publicly appointed and EU-certified experts can act in an advisory capacity when purchasing machinery. Experts provide valuable support to ensure that the machine purchase is successful and takes all relevant technical aspects into account.

The risk of a faulty delivery of a machine or even a defective machine is significantly reduced

The expert role in machine purchase includes, for example:

- Appraisal of used machines: The expert can assess the used machine as part of an on-site inspection before purchase and identify potential risks at an early stage.

- Technical advice: An expert can provide technical advice to ensure that the selected machine meets the specific requirements and needs of the buyer. This may include review of technical data sheets, specifications, and design features.

- Valuation and assessment of value: In the case of used machines, the expert can carry out an assessment.

- Technical audits: The expert can review technical agreements between the parties to help ensure that significant technical aspects have been adequately addressed.

- Determination of defects: In the event of defects, the expert can assist in determining the causes.

- Preservation of evidence: In the case of a defective machine or a defective delivery, the experienced expert can prepare a substantiated preservation of evidence report to efficiently get to the heart of the technical problem.

- Arbitrator‘s award: Disputed issues can be resolved very quickly between the customer and supplier in a legally binding manner.

- Conciliation and mediation: In case of disagreement between buyer and supplier/manufacturer, the expert mediator can act as an impartial mediator and bring about an agreement.

Publicly appointed experts in Germany are independent and work without being bound by instructions when it comes to clarifying technical issues in connection with the purchase of machinery or a defective delivery.

Conclusion and final thoughts

Buying a machine can be a complex process with inherent risks. In the event of technical errors or defects occurring, it is critical that buyers understand their rights and know the appropriate steps to take to correct the problem.

The first key action is to determine the cause of the error or defect.

Due to the often significant amounts in dispute and the potential impact of downtime due to a defective machine delivery, it is recommended that an expert be involved at an early stage.

This can already be done when defining the requirements for the machine purchase or at the latest when the defective delivery of the machine indicates a case of damage.

In the event of a defective machine, this usually leads to considerable time and cost problems in the manufacturing industry. Therefore, it is advisable to take a professional approach right from the start. Professionals who have extensive experience in machinery as well as in legal disputes, especially as court experts, can help to significantly minimize, although not 100% eliminate, the risks associated with the purchase of machinery.